16

02/2022

The highlights of the Colombiatex fair:

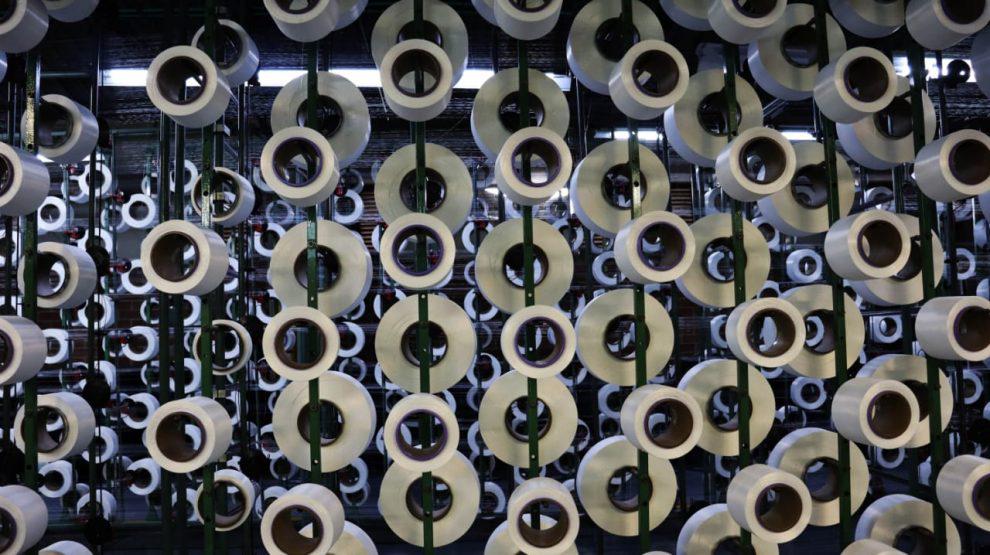

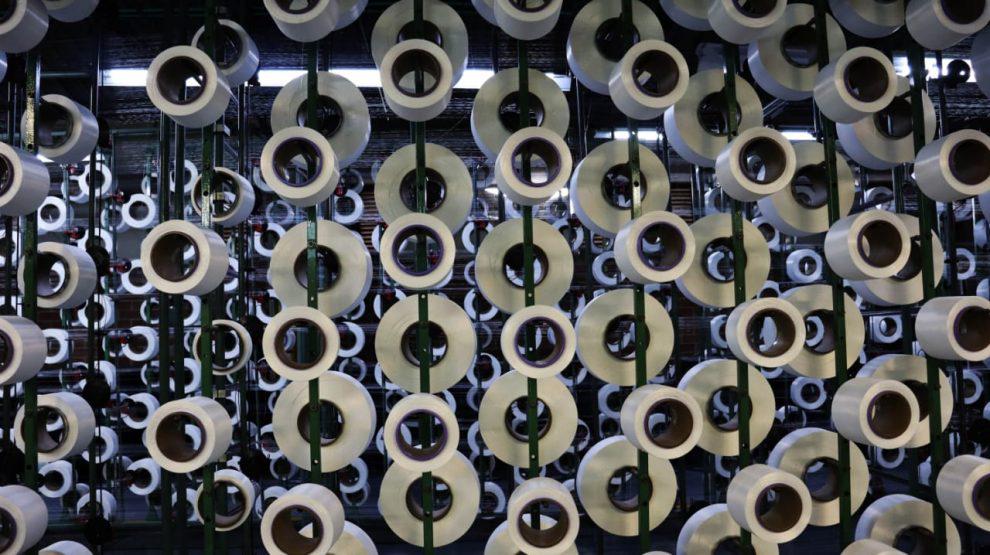

The textile industry resumes its direct participation in the Colombiatex 2022 face-to-face fair that will take place from January 25 to 27, 2022 in Medellín. In this meeting, the exhibitors will offer the most up-to-date sample of raw materials for the clothing and fashion sector in Colombia.

From Brazil

With a varied sample of textile developments and supplies for the clothing sector, companies like Berlan arrive from Brazil with advances in mesh fabrics for the fashion, sports and swimwear segments. The latest in Brand Textil printing and prints, with an innovative sublimation technique that allows an immense variety of personalization of photographic products applied to different types of fabrics.

For the denim segment, Canatiba has a sustainable proposal and "Eko", with fabrics that contribute to the preservation of the environment, under ecologically responsible processes and that have in their composition a mix of sustainable, recycled and certified fibers. Santista Jeanswear with its new 2023 summer collection, with three design lines Icon, Free and Flats.

Additionally, other companies will participate, such as: Cataguases, Cedro Textil, Coltex, Covolan, Dalila Textil, Diklatex, Paranatex, Salotex, Kalimo, Sancris, Santaconstancia, Santana Textiles, Santanense, Spa Textil, Textil J. Serrano, Linhas Triché and Vicunha, which bring developments for the Colombian fashion industry.

During the event, Brazil also has an institutional space where the trends and innovations forum will be presented, with the largest portfolio of products of the companies associated with the Texbrasil program.

This delegation of 22 companies arrives at the event with the support of the Texbrasil Internationalization Program, created by the Brazilian Association of the Textile and Fashion Industry, Abit, and the Brazilian Agency for the Promotion of Exports and Investments, ApexBrasil.

If you want to be happy, start with compassion for others. Read about “How to Cultivate Compassion in Your Life” - http://t.co/3tzwburQsS

— Reuel Hunt Tue May 05 13:15:33 +0000 2015

in the fiber market

The world leader in the development of innovative solutions for the textile industry, the Lycra® Company, presents its new technology: LYCRA® ADAPTIV, a new fiber that allows clothing to better fit different lifestyles, movements and different body shapes. body, as it has a unique composition that allows the fabric to adapt to the functional needs of the wearer in a hybrid way, meaning that when the wearer is at rest, the polymer adapts its compressive strength to provide fit, proper shape and control, and when the wearer is in motion, the polymer adapts its elasticity to provide more comfort and a second-skin effect, keeping the garment in place.

Another innovation is LYCRA® FitSense™ technology, a revolutionary innovation that transforms garments by adding lightweight, localized power exactly where it's needed. This technology is a proprietary water-based dispersion that is solvent-free and includes the same molecule as LYCRA® fiber. The dispersion is made directly inside or outside the garments and. allows you to create intimate apparel, shapewear or active wear without compromising comfort, breathability and durability.

Within its initiatives, which include a circular economy, the company launched its first yarns made 100% from textile waste: COOLMAX® EcoMade and THERMOLITE® EcoMade. These yarns are the first in a series of innovations, based on the recycling of textiles and clothing. It is a unique depolymerization and refining process used to convert textile waste, which consists of leftovers from the production of clothing manufacturers, into fibers with properties comparable to virgin polyester.

From Colombia

The textile and clothing industry in the country has been working to obtain a model that takes advantage of each resource in the companies' value chain; reducing, reusing and recycling the elements that intervene in the different processes. A Colombian company of more than 40 years, Laces SA will offer a sustainable offer as an important contribution to environmental care and as a corporate commitment, Laces SA continues to strengthen its GO GREEN® line, the one with the largest exportation, due to the infrastructure and responsible process at the time to develop the yarn, and with which it has achieved global certifications such as OEKO-TEX and GRS.

GO GREEN® is a collection that has been developed using recycled Nylon that, thanks to its recycling process, has a 50% reduction in the environmental footprint left by the production of each kilo of yarn. The recycling of pre-consumer yarn allows the elimination of about 70% of the extraction of natural resources and production processes.

As a complement to the integrated and sustainable supply of textiles, the category of control garments appears, which continues to strengthen in the national and global market. At the export level, lace made from special technologies such as the GO GREEN® line and SKIN SOFT continue to be the most in demand. During 2021, microfibers with differentiated weight and touch were the most popular.

Share on FacebookShareShare on TwitterTweetShare on PinterestShareShare on LinkedinShareShare on DiggShare

- 1130

- What is fashion and clothing technology?

Related Articles

48 Best Kids Watches in 2021 based on 623 reviews

16/05/2022If you are here, we assume that you are looking for the best watches for children. However, given the number of options available in the market, it becomes really daunting to choose the right product...

46 Best Pitchers and Decanters in 2021: According to the Experts

20/04/2022You can get any random Pitchers and Decanters, but if you're looking for expert advice to choose the best one for your needs, then you've come to the right place. No matter which...

39 Best Legumes in 2021: According to the Experts

02/03/2022You can get any random legume, but if you're looking for expert advice to choose the best one for your needs, then you've come to the right place. No matter what your...

Best Camper Kit For Vans 2022 (buying guide)

03/05/2022Technology improvement need only increase the level of competition in each market. Whether it is automobiles or electronic devices, every industry makes the best use of advanced technology...